In Cebu’s competitive commercial landscape, where water quality directly impacts product integrity, operational costs, and brand reputation, investing in a robust Commercial Reverse Osmosis System Cebu is paramount. For industrial and commercial clients, RO technology represents the most effective barrier against contaminants, guaranteeing the high-purity water necessary for precise processes. Kemique Water Soluzione provides tailored RO solutions, ensuring businesses achieve optimal performance and compliance.

The Economics of High-Purity Water

While the initial investment in a Commercial Reverse Osmosis System Cebu may seem substantial, the long-term economic benefits far outweigh the costs of using untreated or poorly treated water, especially in a region with naturally hard water like Cebu.

1. Cost Reduction through Scale Mitigation

Cebu’s water sources often contain high concentrations of calcium and magnesium ions, leading to scaling in utility equipment.

- Boilers and Heat Exchangers: Scale acts as an insulator, drastically reducing heat transfer efficiency. This forces boilers and heaters to consume more fuel to achieve the target temperature. An RO system, by removing the scale-forming minerals, ensures utility systems run at peak efficiency, generating significant energy savings and reducing the frequency of costly chemical descaling procedures.

- Reduced Blowdown: For high-pressure boilers, RO-treated feed water (with very low Total Dissolved Solids or TDS) requires less blowdown (draining of concentrated water), conserving water and saving energy used for heating.

2. Product Quality and Consistency

In sectors like food and beverage and pharmaceuticals, inconsistent water quality can lead to product defects, batch failures, and expensive recalls. An RO system provides a stable, repeatable standard of water purity, which is critical for consistent product quality and meeting international manufacturing standards (e.g., ISO, GMP).

3. Reduced Chemical Consumption

Pre-treatment with RO significantly lowers the need for aggressive chemicals used in later treatment stages. For instance, less chemical softener is needed in boiler feed water circuits, reducing chemical purchasing costs and simplifying chemical inventory management.

Technical Deep Dive: RO System Components and Feed Water Challenges

A high-performance Commercial Reverse Osmosis System Cebu is defined by the quality of its components and the precision of its pre-treatment steps, which are dictated by Water Analysis Services Cebu reports.

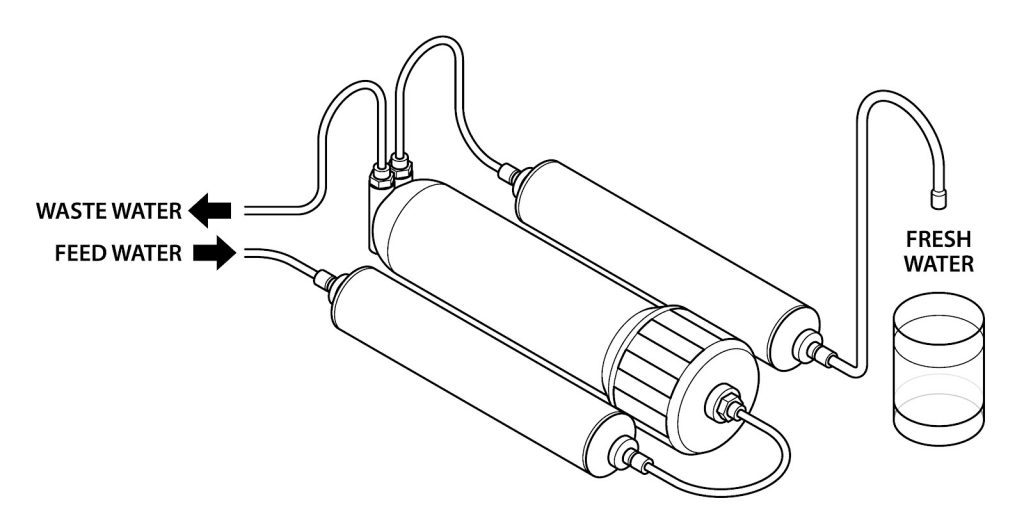

The RO Membrane and Pressure

The core of the system is the semi-permeable membrane

. The feed water is pressurized by a high-pressure pump to overcome the natural osmotic pressure, forcing pure water across the membrane while rejecting the dissolved contaminants.

- Salt Rejection Rate: Quality membranes achieve a salt rejection rate of 98% to 99.5%. The remaining rejected contaminants are flushed out as concentrate or brine (which must be properly managed according to DENR effluent guidelines).

- Operating Pressure: The required operating pressure is directly proportional to the TDS of the feed water. Since Cebu’s water can be high in minerals, the system must be designed with a powerful, energy-efficient high-pressure pump.

Mitigating the Cebu Water Profile: Pre-Treatment

The major threats to an RO membrane in Cebu are scaling (from high hardness and silica) and fouling (from organic matter and particulates). Effective pre-treatment is the solution:

- Antiscalant Dosing: Based on the feed water analysis, a chemical antiscalant is continuously injected upstream of the membranes. This prevents the crystallization of difficult-to-remove contaminants like calcium carbonate and silica on the membrane surface.

- Silt Density Index (SDI) Control: Particulate matter can clog the fine pores of the membrane, a process called particulate fouling. Regular monitoring of the SDI (an indicator of fouling potential) and the use of robust Multi-Media Filters and fine Cartridge Filters are essential to maintain membrane lifespan.

- Chlorine Removal: Chlorine, often used in municipal water to kill bacteria, will irreversibly damage the delicate RO membrane material. Activated Carbon Filters or chemical dosing (using sodium metabisulfite) must be used before the RO unit to fully eliminate residual chlorine.

Service and Partnership: The Kemique Water Soluzione Approach

For Cebu businesses, the reliability of the Commercial Reverse Osmosis System Cebu depends heavily on the service provider’s expertise and local presence.

Proactive Operation and Maintenance (O&M):

- System Monitoring: Implementing regular checks on key performance indicators (KPIs) like Product Flow Rate, Salt Rejection Rate, and Trans-Membrane Pressure (TMP) helps detect fouling or scaling issues before they cause a system shutdown.

- Clean-In-Place (CIP): When performance drops, Membrane Cleaning (CIP) restores the membrane’s functionality. This involves circulating specialized, high- and low-pH cleaning chemicals through the system. A local service provider can execute this complex procedure rapidly and efficiently.

- Local Spares Inventory: Maintaining a local stock of critical components (e.g., high-pressure pump seals, flow meters, RO Antiscalants, and replacement membranes) in Cebu City minimizes lead times for repairs, ensuring clients’ operations face minimal interruption.

Future-Proofing Water Supply in Cebu

As water scarcity increases and environmental regulations tighten, the role of a Commercial Reverse Osmosis System Cebu will evolve. Future solutions will focus on maximizing water recovery and minimizing the volume of brine discharge. By partnering with local experts like Kemique Water Soluzione for high-quality Water Analysis Services Cebu, commercial operations can secure a pure, stable water supply, ensuring profitable growth while adhering to the highest standards of environmental stewardship in the Philippines.

0 Comments